Making the case for Heartland manufacturing is simple: Lower costs, superior location and logistics, and a workforce built for higher performance. In short, higher standards, faster delivery and competitive costs.

In the nation’s 10th largest manufacturing state, the Heartland offers all the right advantages for global industry.

Optimal Operation Costs

In a region where both costs of living and operations are significantly below more urban areas, manufacturers will discover affordable, abundant acreage and operational advantages such as competitively priced and reliable, responsive energy service by pro-business utilities. These include Duke Energy and Florida Power & Light, as well as Peace River, Glades and Lee County Electric Cooperatives.

The Heartland also facilitates faster ROI with incentives including two Foreign Trade Zones, workforce development incentives, state-designated rural incentives and targeted manufacturing incentives.

Central Location. Rapid Global and Domestic Delivery.

The Heartland positions manufacturing for rapid reach to all points in Florida, including convenient access to seven deep water ports on both the Gulf and the Atlantic. Highway connections include three interstates, four U.S. highways and 12 state highways, while CSX rail in conjunction with short line service provides blanket coverage of the Eastern U.S. Leverage the flexibility of port, highway, rail and a strategic air network that offers local, regional and international connections.

A Purpose-Built Powerhouse Development Infrastructure

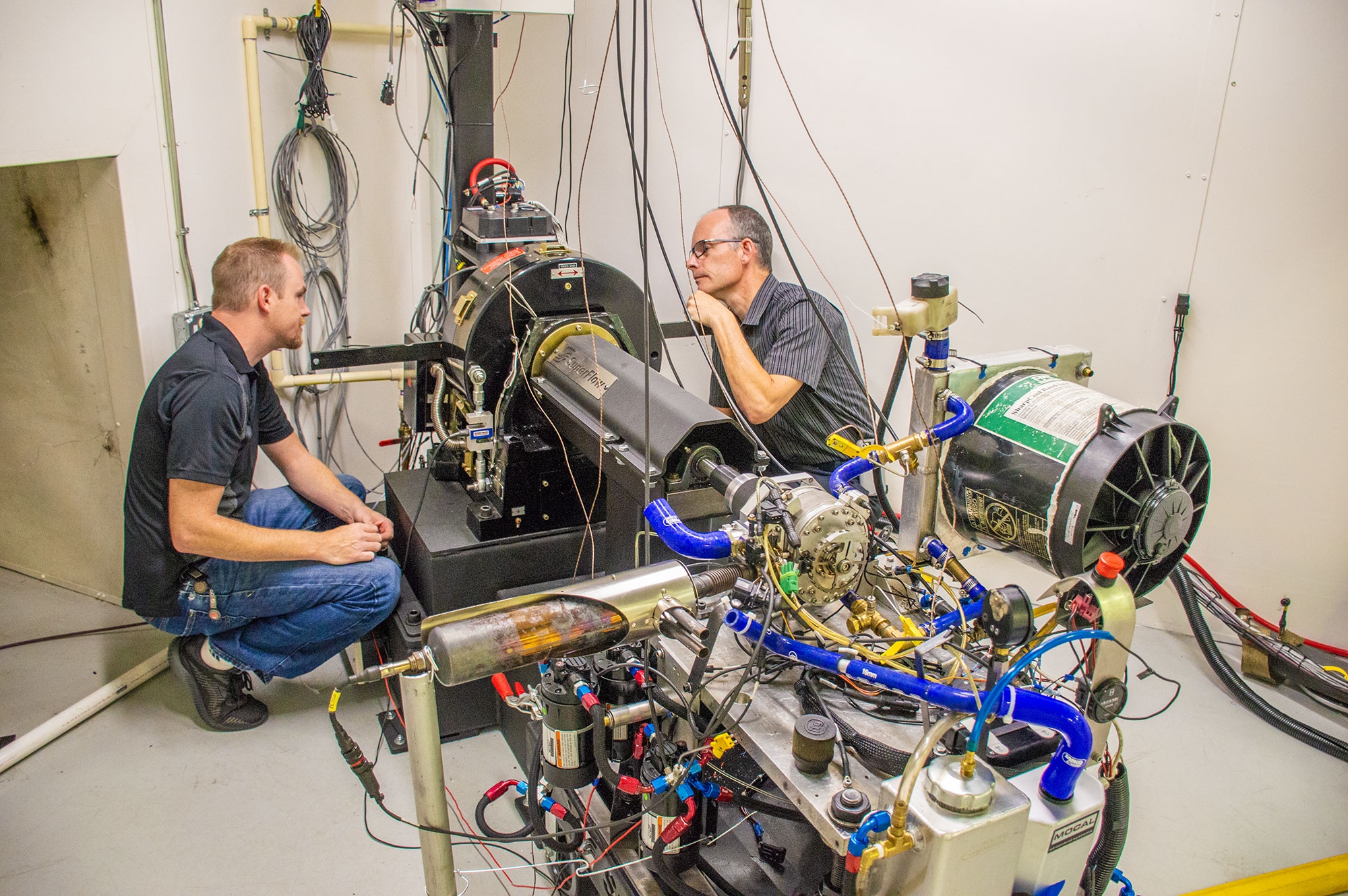

Focus, funding and facilities: That’s the workforce development difference that sets the Heartland apart. A rich agricultural heritage has made diligence second nature here, and as the economy has diversified, that diligence has resulted in a development infrastructure second to none. The Heartland has built a better workforce from the ground up, beginning with aligned programming at nearly a half dozen area colleges covering needs such as CNC and machining technologies, production technology, pneumatics, hydraulics, mechatronics and more.

And by leveraging millions in funding, the region has built training facilities that answer current and future needs with the highest level of technology for immersive training experiences. At the 60,000 sq.-ft. Eastman Advanced Workforce Training Complex, state-of-the-art training includes advanced and additive manufacturing; robotics and smart automation; automotive, aviation and marine technology; welding and more.

While aligned programming assures a performance-ready workforce, no- and low-cost custom training is also available for qualified projects through CareerSource Florida. CareerSource also provides one-stop recruitment, screening and hiring. For more information about workforce development incentives, click here.